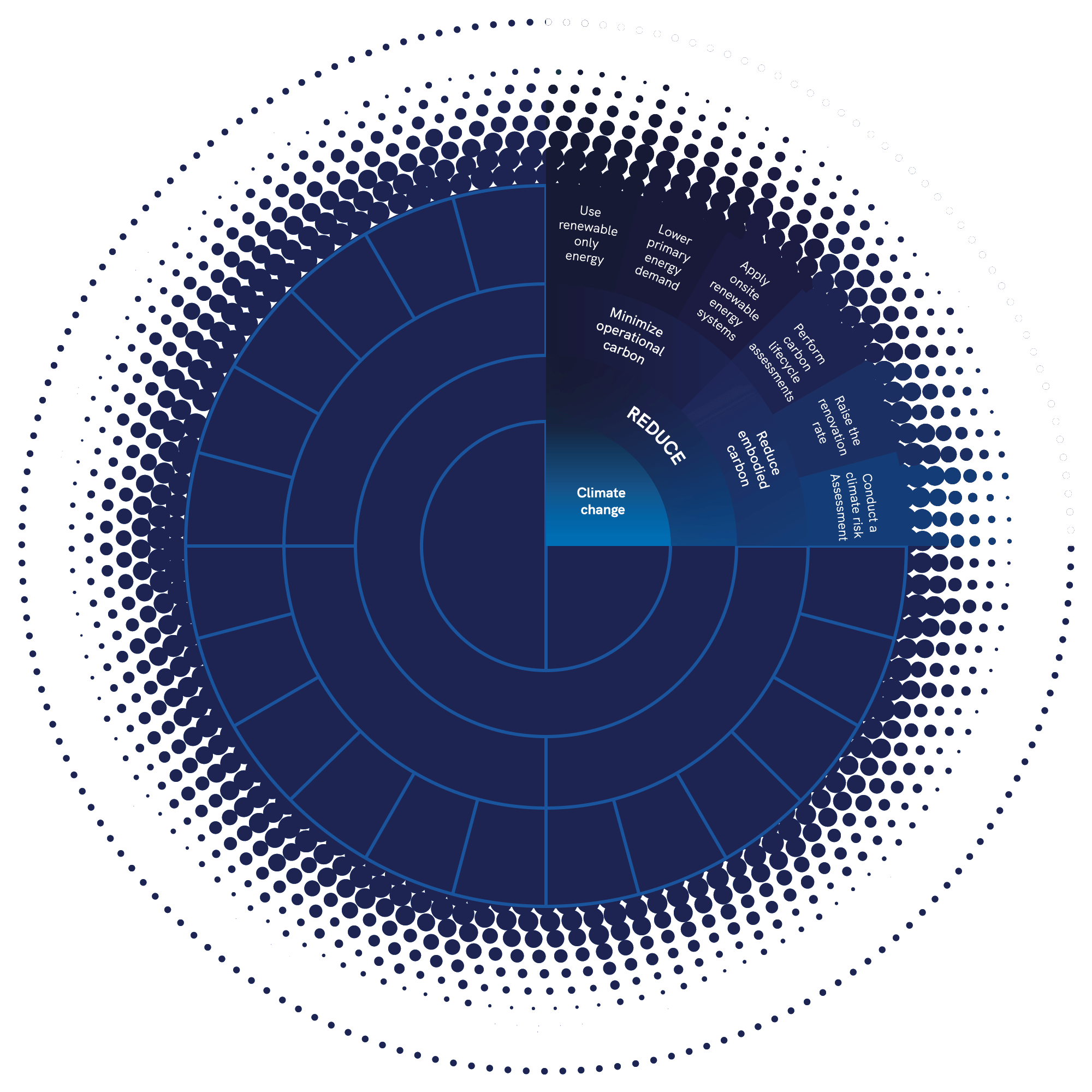

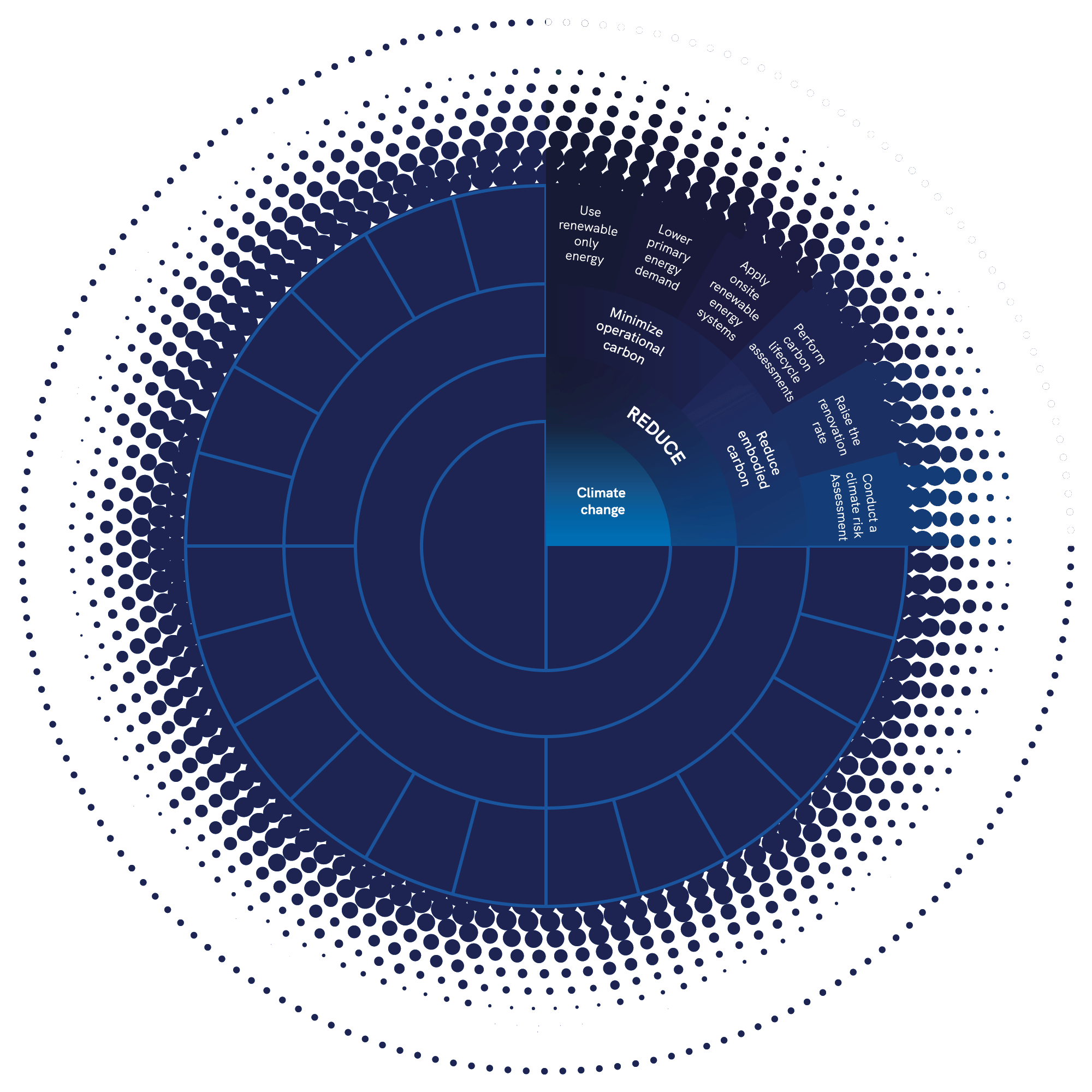

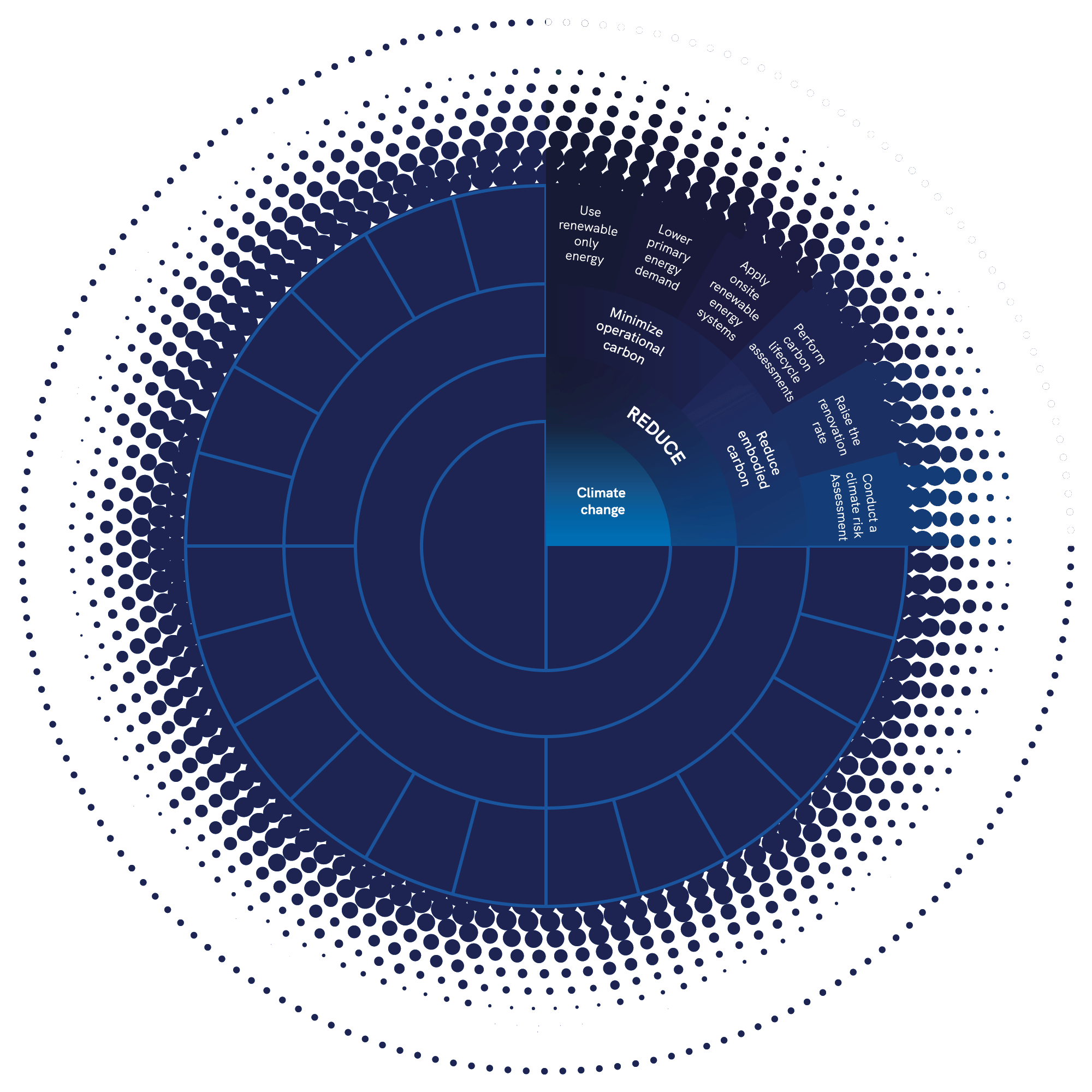

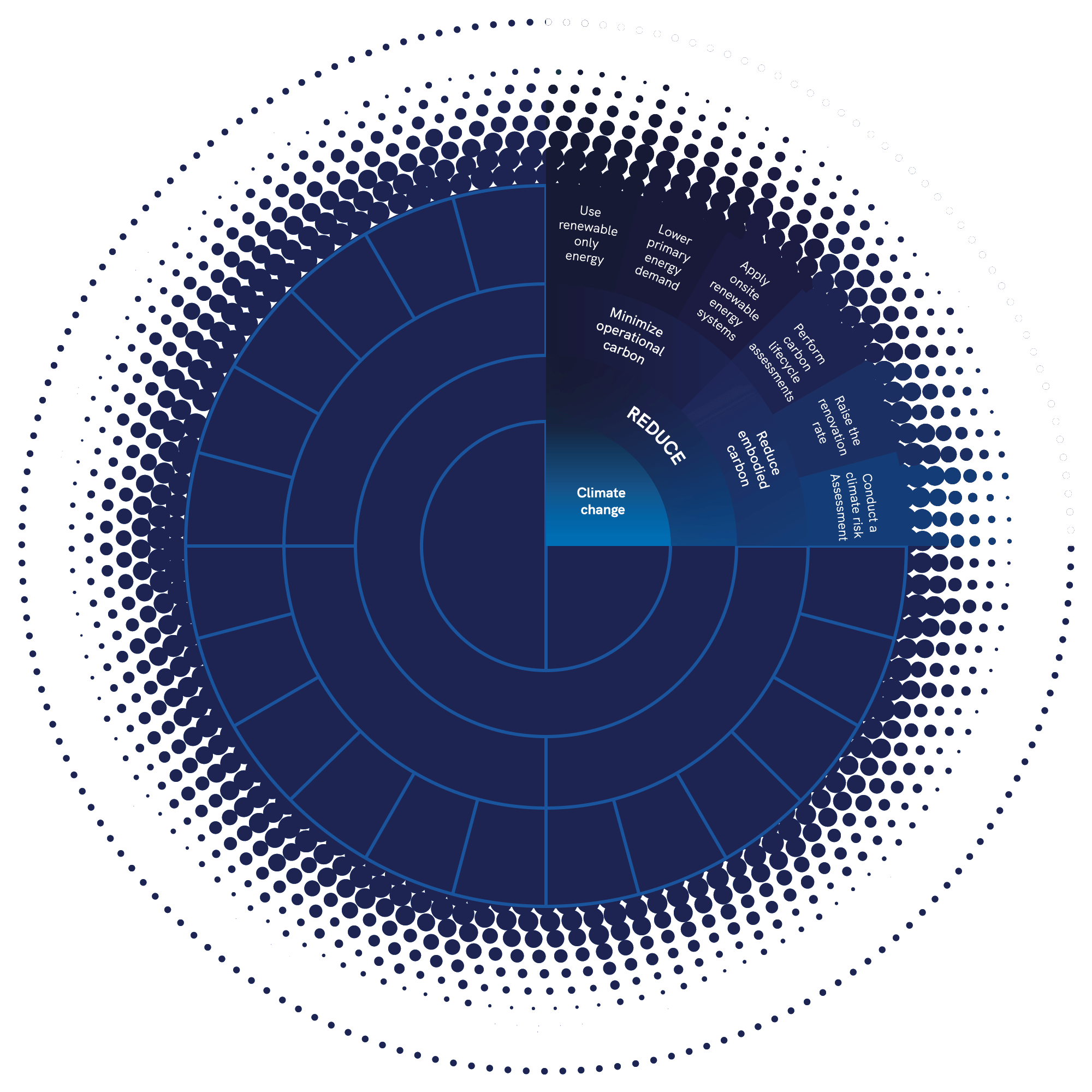

REDUCE – CLIMATE CHANGE

MINIMIZE OPERATIONAL CARBON

Use renewable energy only

Lower primary energy demand

Apply onsite renewable energy systems

REDUCE EMBODIED CARBON

Perform carbon lifecycle assessments

Raise the renovation rate

Conduct climate risk assessment

100%

6

Since 2019, Revive has offered products powered entirely by 100% renewable operational energy, a landmark achievement that came six years ahead of any legal requirements.

1st

41%

Ambitions

Average footprint of 400 kg CO2 eq/m2 by 2030

Our goal for 2030 is to achieve an average footprint of 400 kg CO2 eq/m2. By increasingly focusing on the reuse of buildings, we aim to reach 250 kg CO2 eq/m2 by 2035. While the exact path to a net-zero target is not yet entirely clear, we are confident that a combination of innovations, sustainability efforts, and partnerships will make it achievable.

Ongoing pioneering in climate-neutral

At Revive’s pipeline project Marie Thumas in Leuven we have started a pilot for a heat network combining aquathermal, geothermal and solar energy together. The combination of energy from water, soil, air and sun should ensure that the entire area can be climate-neutrally heated and cooled. This is a first in Flanders. At the Vynckier site in Ghent we are investigating the feasibility of a district heating network that connects waste heat from local industrial production processes to the new buildings, as well as Riothermie, which involves using heat from wastewater.

Modular building

We are planning to implement modular building techniques in our project pipeline. Modular construction offers numerous benefits, including reduced waste, higher potential for material reuse, and the use of eco-friendly materials.

Cases

First circular concrete – Komet

First heat network - Minerve

CLT construction - Tannat

First circular concrete – Komet

In December 2021, our Mechelen based project Komet was the first building

project in Belgium to use recycled concrete. The construction of the second

phase of Komet required about 15.000 m2 of concrete, 5.000 m2 of that is recycled (green) concrete. This corresponds with a saving of some 1.500

tonnes of natural concrete aggregate, or, 50 large trucks driving from quarries

in Wallonia to the site, accounting for 7.500 km of heavy transport.

First heat network – Minerve

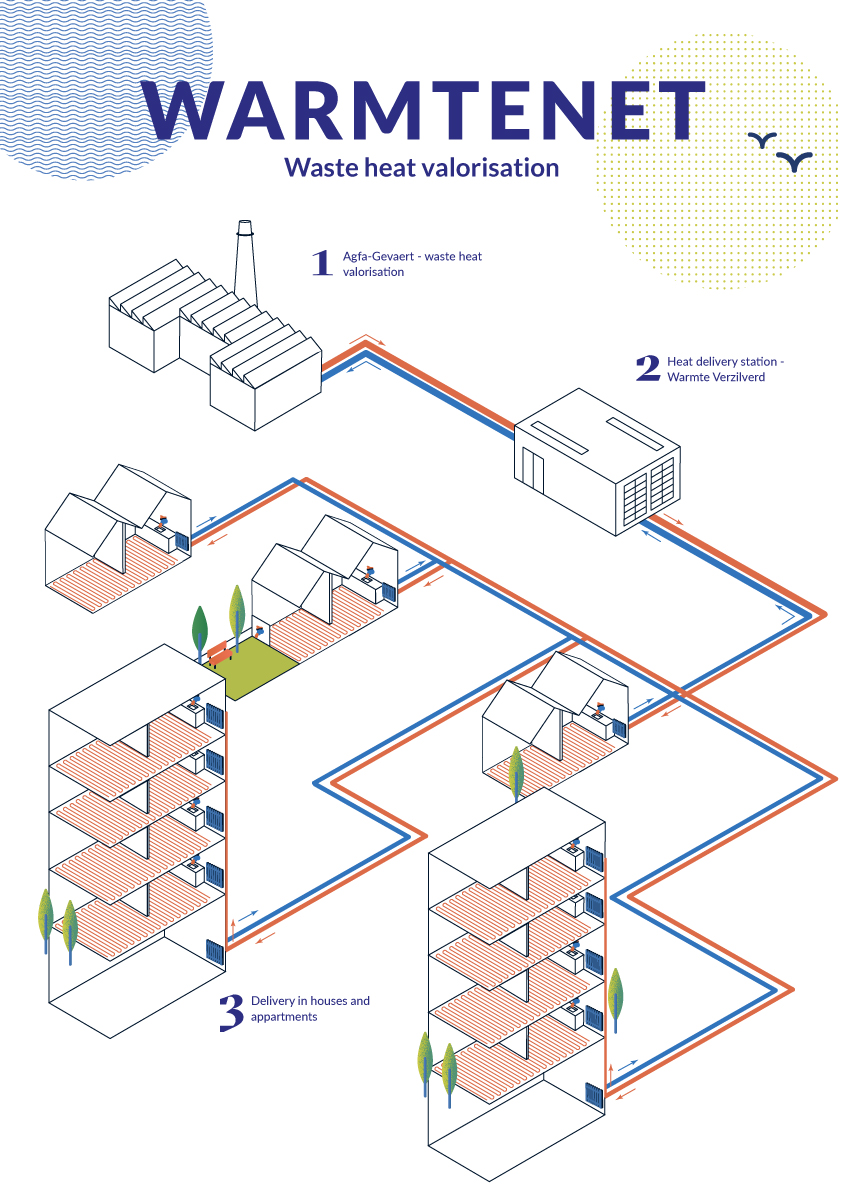

In 2020 Revive and its partners build a cooperative heat grid at the Minerve site in Edegem (Antwerp). This was not the first heat network in Antwerp, but the first heat network using industrial residual heat to heat nearby homes and buildings.

As a result, some 300 homes will be heated by the residual heat from the industrial processes of the neighbouring Agfa-Gevaert plant. The company had been focusing for years on energy efficiency – including absorption cooling and heat pumps – but there was still a great deal of potential to recover additional energy.

CLT construction – Tannat

We aim for Brussels based project Tannat to remain innovative even 10 years from now. Therefore, we focus on a future-oriented project that utilises cutting-edge materials, including solid wood construction or CLT (cross-laminated timber), self-supporting bricks, and hemp-lime insulation, with an eye on circular principles. The wood used in CLT panels is PEFC-certified. In fact, wood stores 1.800 tons of CO2 instead of emitting it by using traditional construction materials.